Superior Microbial Barrier protects your device’s sterility

DuPont™ Tyvek® Healthcare Packaging

Coronavirus (COVID-19) Outbreak Alert: Read FAQs about DuPont™ Tyvek® Healthcare Packaging and DuPont's response for protection and control →

See also:

- Tyvek® Packaging for Sterile Swabs is an important component in packaging medical devices for COVID-19 testing

- DuPont™ Tyvek® Supports In-Hospital Decontamination of Used N95 Respirator Masks

No Compromise. Because life matters.

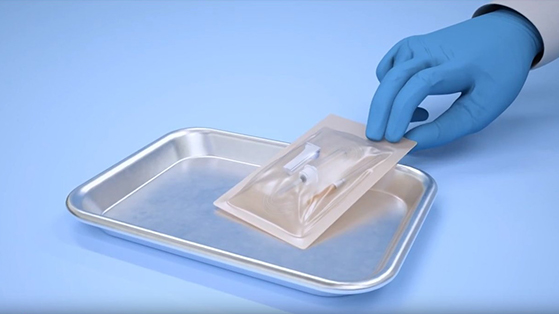

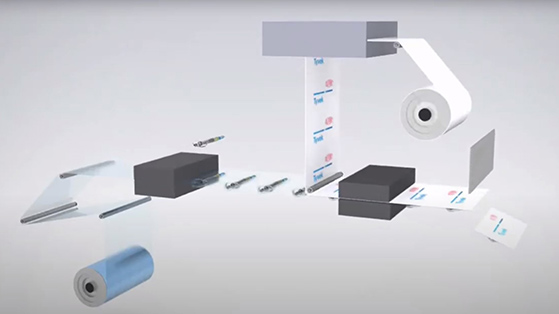

DuPont™ Tyvek® Healthcare Packaging provides the tear resistance, durability, breathability, clean peel and superior microbial barrier to keep medical equipment and pharmaceuticals sterile throughout their lifecycle—protecting the health and well-being of millions without compromise.

Unlike medical-grade papers and films, Tyvek® is compatible with all of the most commonly used sterilization methods, including:

- Ethylene Oxide (EO)

- Radiation (Gamma and electron beam)

- Steam under controlled conditions

- Low-temperature oxidative

Tyvek® has been a trusted choice for medical device and pharmaceutical manufacturers as well as specialized sterile packaging suppliers worldwide for decades. Because Tyvek® is made from HDPE, it can also be recycled, according to local regulations.

Learn more about how we are advancing sustainability in healthcare packaging with Tyvek®.

Products for Healthcare Packaging

Tyvek® 1073B

Tyvek® 1073B provides the highest level of protection, making it the ideal choice for medical device and pharmaceutical packaging that requires high strength and superior microbial barrier.

Tyvek® 1073B

Explore

Tyvek® 1059B

Tyvek® 1059B provides robust protection for medium-risk, sterile medical packaging applications. Lighter weight than Tyvek® 1073B, this proven performer is ideal for smaller devices and those with rounded edges.

Tyvek® 1059B

Explore

Tyvek® 2FS™

Tyvek® 2FS™, a high puncture-resistant substrate, outperforms paper in terms of toughness and microbial barrier. A light-weight form of Tyvek®, it is well suited for form-fill-seal, as well as cost-sensitive applications requiring strength.

Tyvek® 2FS™

Explore

Products for Pharmaceutical In-Process Applications

Tyvek® 1073B

Tyvek® 1073B provides the highest level of protection, making it the ideal choice for medical device and pharmaceutical packaging that requires high strength and superior microbial barrier.

Tyvek® 1073B

Explore

Tyvek® 1421B

Tyvek® 1421B is specifically developed for in-process pharmaceutical applications to protect surfaces of cleanroom equipment, components and accessories from particle and microbial contamination.

Tyvek® 1421B

Explore

Featured Information

Where to Buy

See our list of Authorized Converters by region

Where to Buy

Explore

Resource Center

Explore Tyvek® through various technical and regulatory documentation